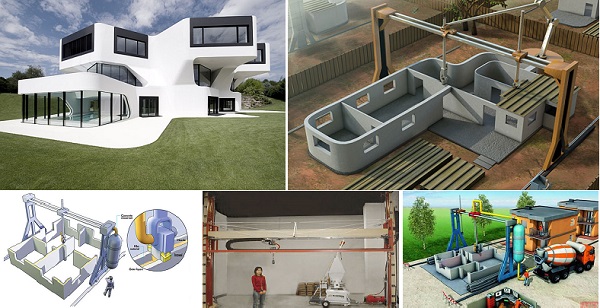

There is a new era in architecture and design that involves nothing more or less than printing, 3D printing. Believe it or not, these are the first steps towards rendering the old traditional world of building with ordinary materials, kind of obsolete. The practical applications are although in particular for creating homes in an emergency situation like disaster areas, where time is of the essence. So, regular architects can rest assured, for now.

The new technology has proved efficiency in other areas as well. Developing and under-developed countries worldwide can provide instant affordable homes, with walls proved to be sturdier than the ones built in a conventional way. The truth is that the possibility of more large residences or buildings raised in the manner of 3D printing is very high, and it has more to do with science and economics than Science-Fiction. The device was developed by Professor Behrokh Khoshnevis (and his team) with the purpose of slashing time and costs of constructions significantly.

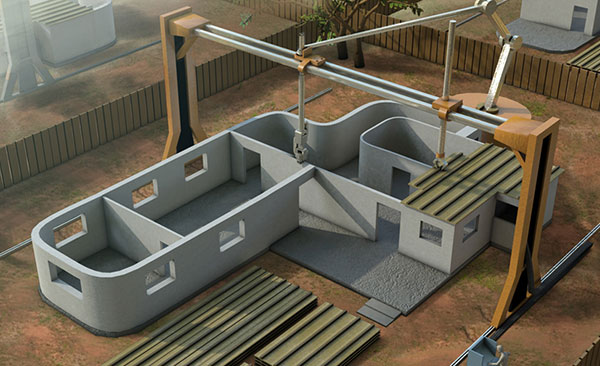

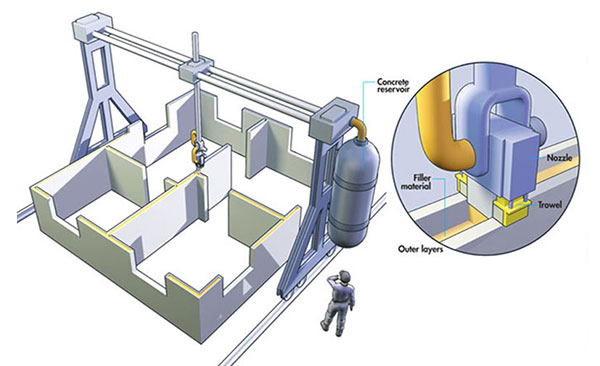

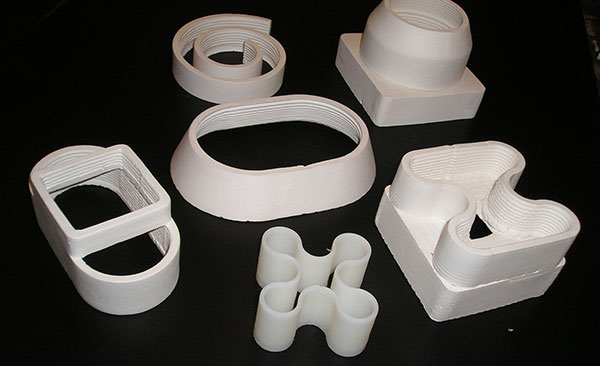

Contour crafting, as it’s now known, is composed out of two rails laid out on leveled construction site. This allows the movement of a computer-controlled arm that shapes the outlines of the structure, while a nozzle fills them with concrete This will create an entire house in no time, comparing to traditional building methods. By crafting sturdy structures and, in the end, houses in few time, the giant 3D concrete printer can easily come up wit a 2,500 sq foot house in no more than a single day, in any design. And if you want to change it, simply change the program on the machine. It’s so easy and convenient for any builder.

sounds good but what about pipes wires and insulation?

It’s all worked in as it goes(conduit). Ive seen other house printing videos, which show it in better detail

How much would one like this cost?

Y que hacemos con los millones de albañiles? Sigamos dándole el trabajo a las maquinas…

What about rebar? you know, tensile strength…

Fiber is replacing rebar more and more these days. Doesn’t rust, provides 3D structural integrity and minimizes cracking.

24 hours?

That means you could move the furniture in and build the house around it. Maybe covering the furniture with plastic sheeting if the printer process is messy but from what I understand that wouldnt be a problem.

Jim, Build the walls in 24 hour with the 3d printer, add electrical an plumbing to the surface of the walls, drill what needs to be drilled (electrician and plumber), nail furring strips (carpenter), apply drywall (Mexicans from Labor Ready), and paint (Painter). Habitable house in 2 weeks!

So, did the professor figure out a way that didn’t reinforcement, ie, rebar or wire.

Sounds cool but probably wont be financially possible for anyone for 20 years. Just like 3d printers years ago they were available but they were super expensive and these will be the same except for the human element. Making these always super expensive and available to only the uber rich.

U$99 square meter finished – just bring your belongings!