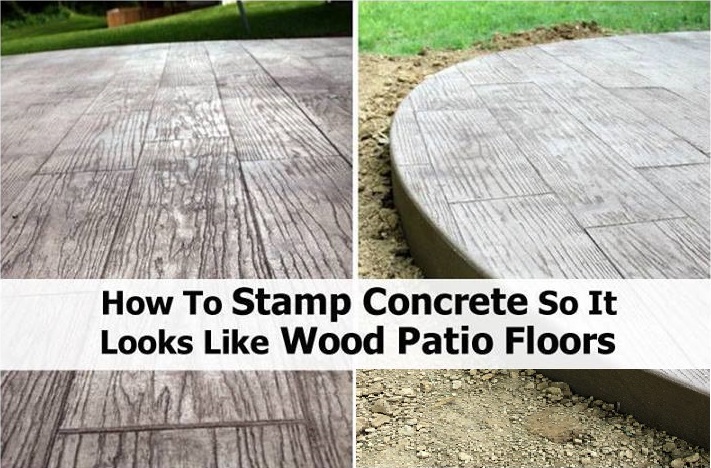

Are you in the process of extending your yard and don’t know a way to succeed in having a great design and money left in your pocket? Make sure your patio is one of the best looking in the neighborhood by choosing a beautiful, cool and inexpensive design. When seeking to improve our homes, we like to get the best result with the littlest of money invested if possible. In the patio department, the costs are commonly high and maintenance can rise up over time to amounts even higher than the actual investment. There is a trick you could use: stamp concrete in a way it will look like a wood patio floor. Invest smartly in your garden design by opting for a creative DIY solution like this one. Read the following tutorial in order to find out what do you exactly need and precisely what are the steps to pulling this off.

More details here… DIY Wood Plank Stamped Concrete

This isn’t a tutorial. It’s a link to a blog by a woman who had a concrete company install a deck and pathway using concrete stamps. The gist of this “tutorial” is “find a contractor to do it for you.”

As Kristy says its a path to go get a contractor, disappointed that the tutorial was a waste of time and did not give any information on doing a diy stamping project, I was expecting information on how to build a stamp and fixing the forms etc.

You can buy these stamps on ebay….then watch videos on youtube. They are fairly easy to do…..

The title is deceiving, this is instructions on how to hire a contractor, which is not a DIY project. But you can buy the stamps online, and there are other how to videos. Good-luck.

Good luck….. This is not a do it yourself project. Most concrete contractors do not offer this service. I do not offer it, but have been called in to help other contractors with stamping projects. It takes heavy expensive rubber stamps, release material, and an additive to the concrete.

waste of time article. no help whatsoever

You can make your own too.. Plywood with a good looking grain + blowtorch. Burn off the soft wood from the face of the plywood to create a 3D surface (you can use a wire brush too) then seal and Poof! a sdtamp.. put a few together to make it fit and cover more area and you are ready to go.

Or you can get a few pieces of rough sawn DRIED lumber the width you want and press it into the smoothed concrete before it dries.

FAIL, why would you want to mislead?

They get paid to blog…..so you end up with this kind of garbage.

Hello! Happy to see this content. I have a browsing topic related to this. I found this website very helpful, thanks for your sharing. I never realized that stamped concrete cape cod is beautiful and easier to maintain. I seek out and try to improve my home every day as well as carry out some DIY solutions after getting married for around 6 years in Ma, now I have a great boy and try to teach him how to take care of our garden. Keep posting!